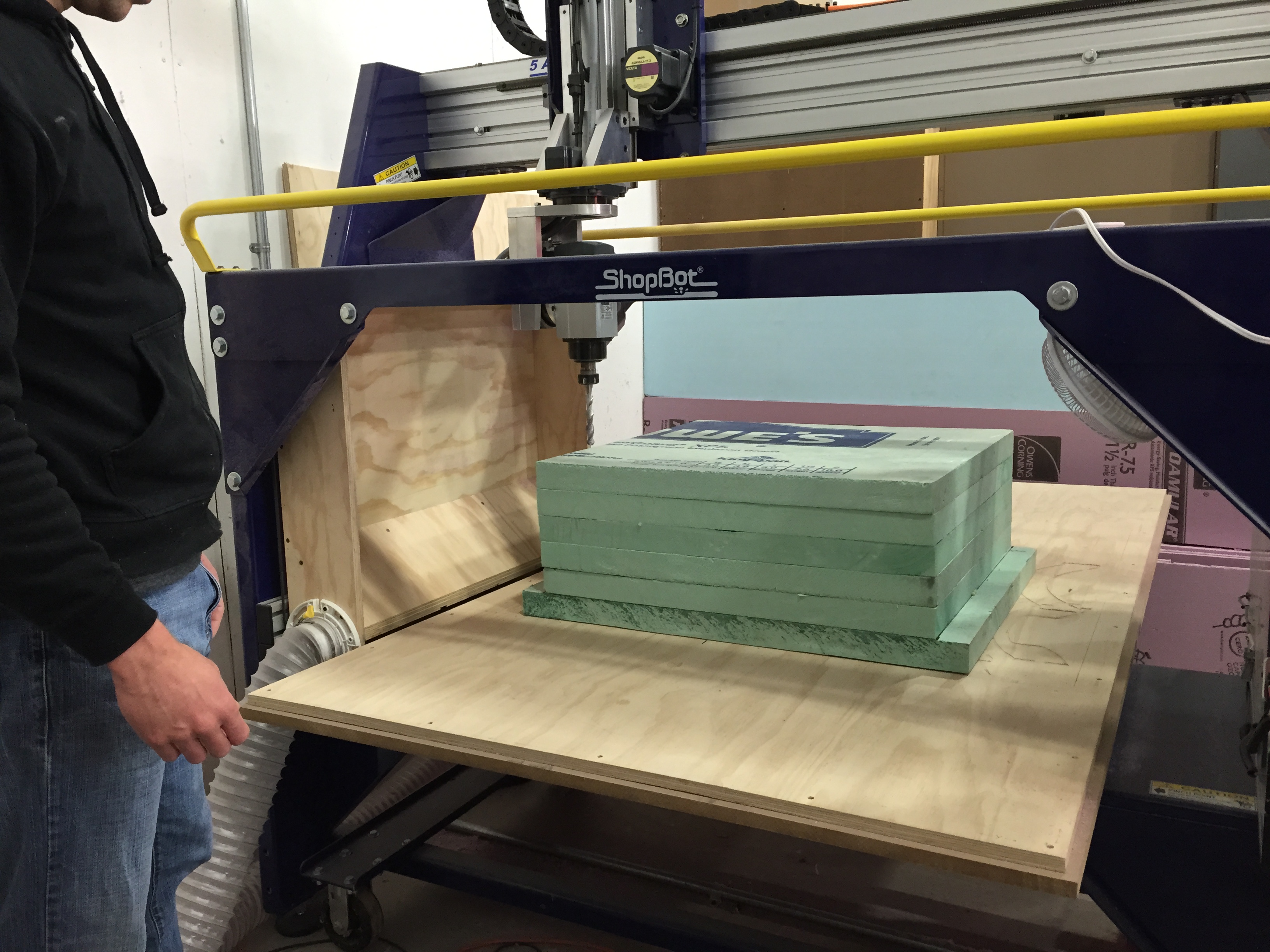

For my second project I used the CNC router to create relief carvings in 1 x 4 planks of wood. The carvings were very intricate animals and would have taken an incredibly long time to do by hand. However, the CNS router carved all of my pieces of wood in about 8 hours. Here are some pictures of the process

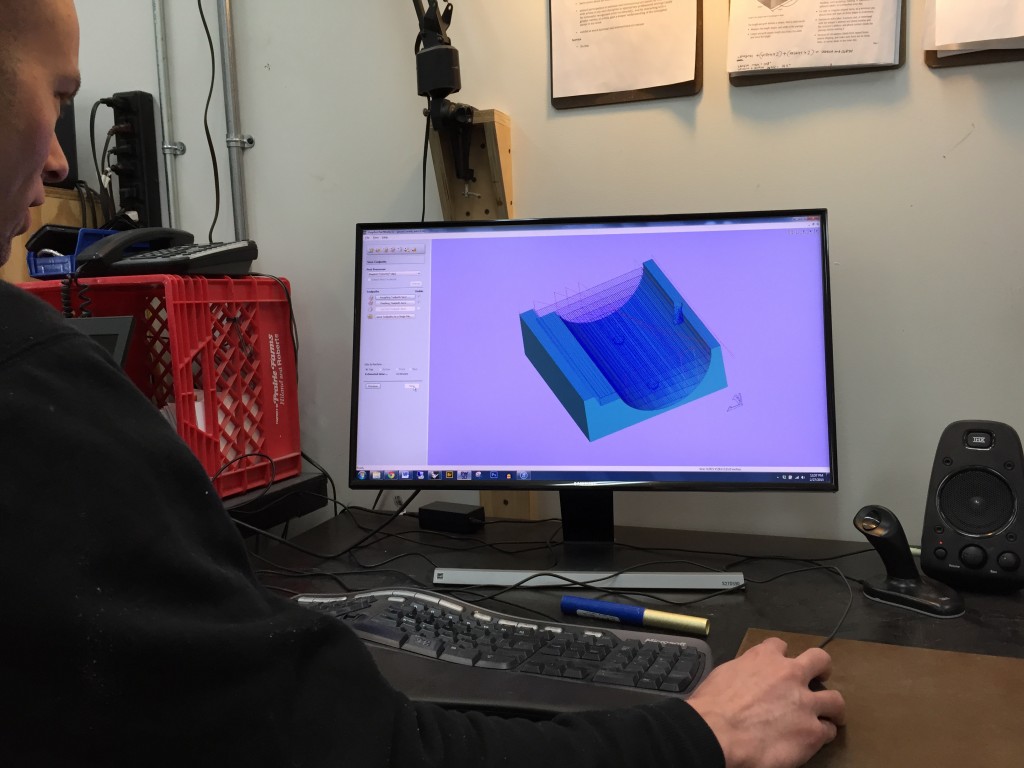

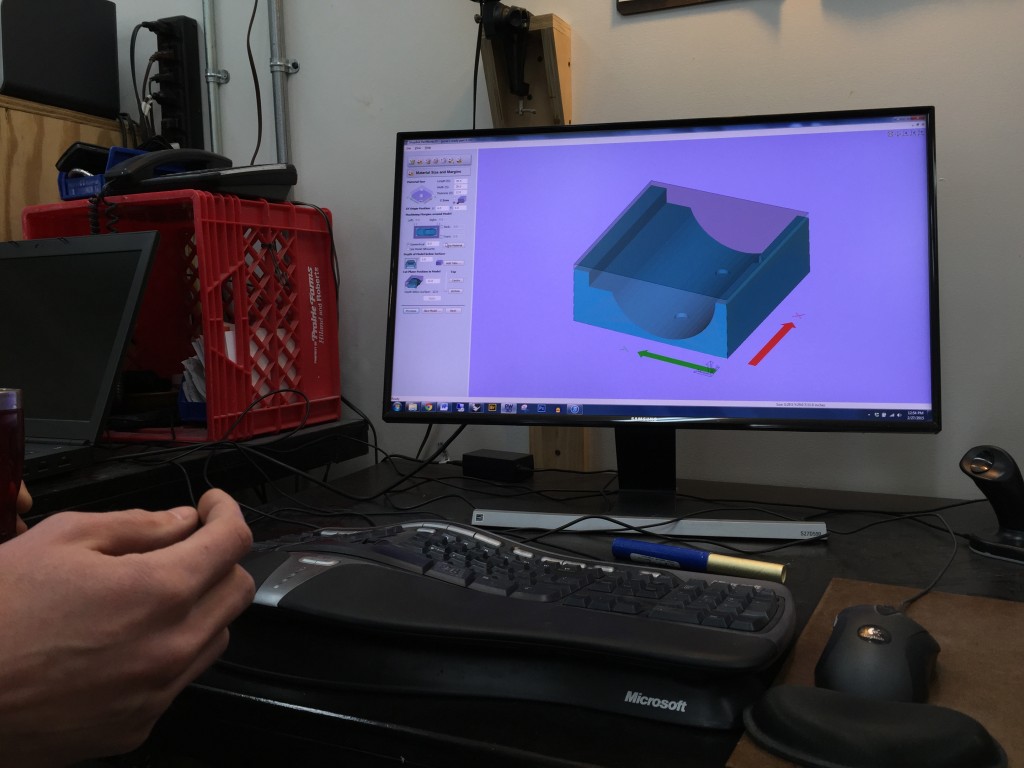

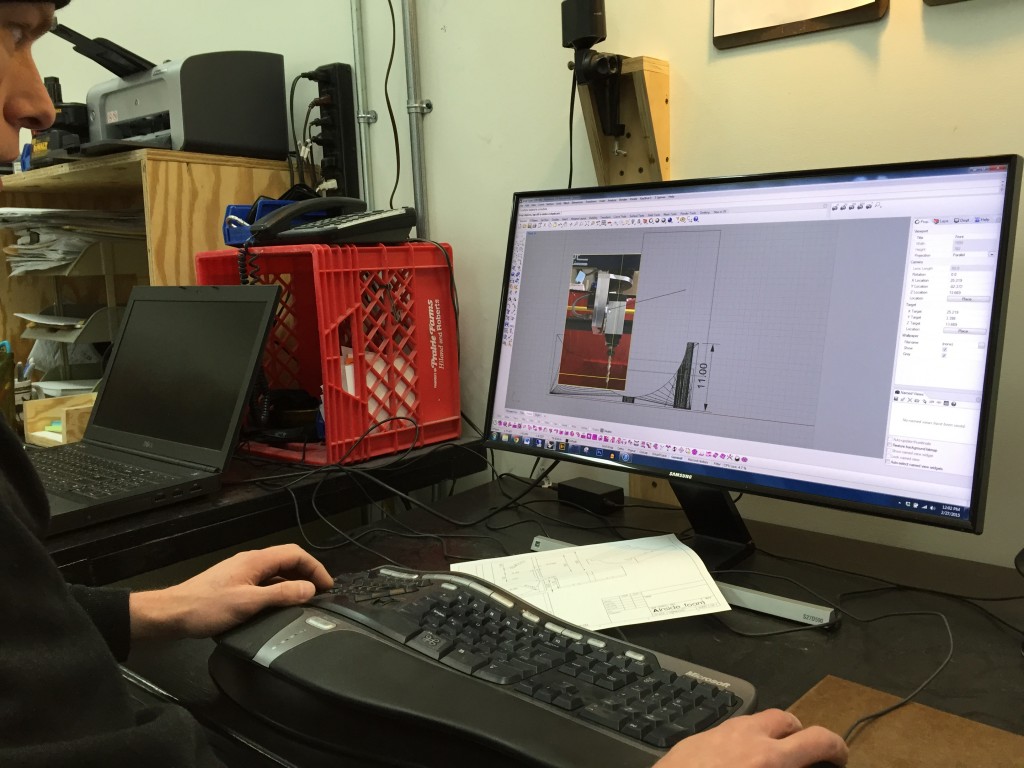

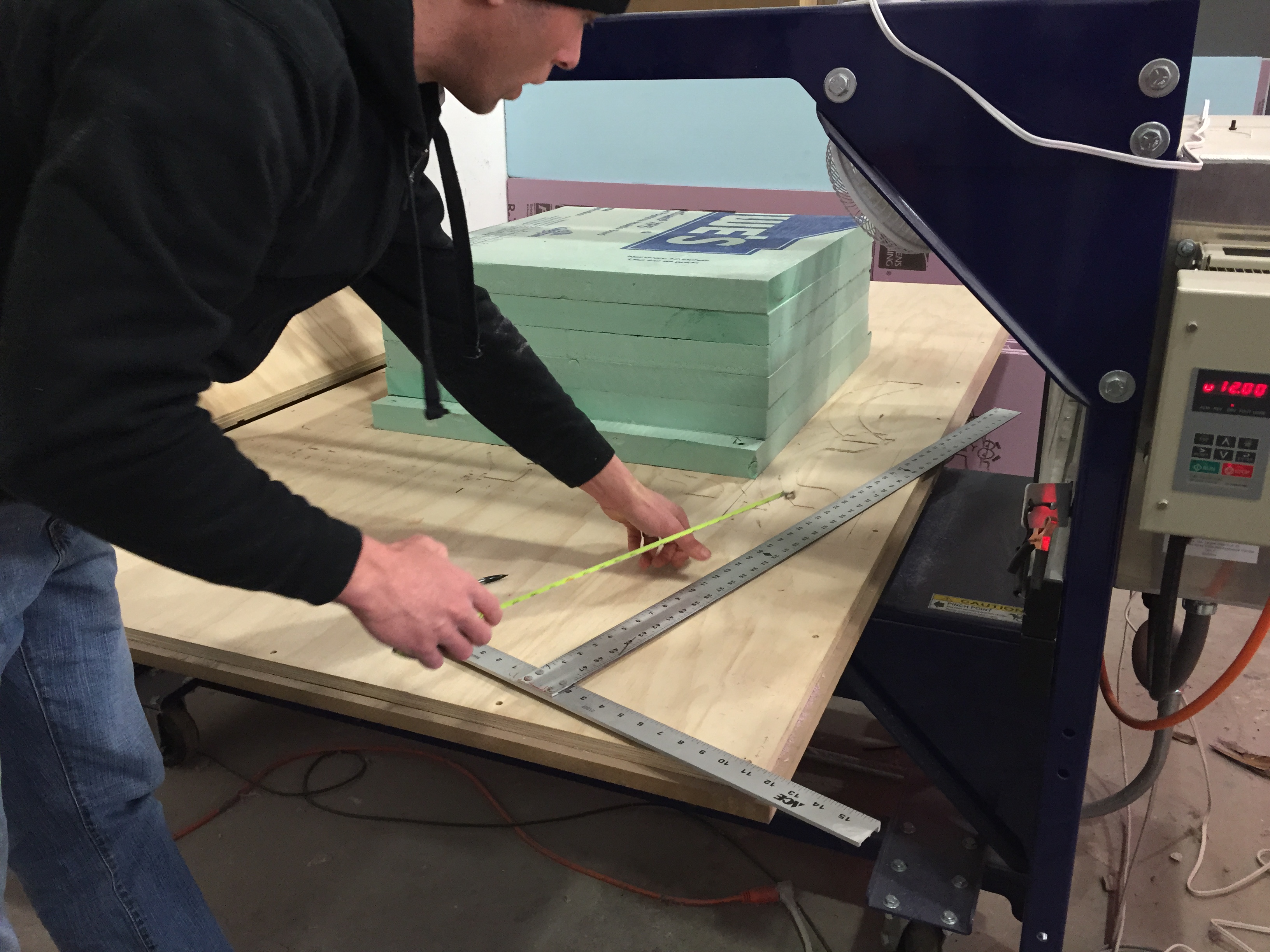

Setting up the cut file for routing

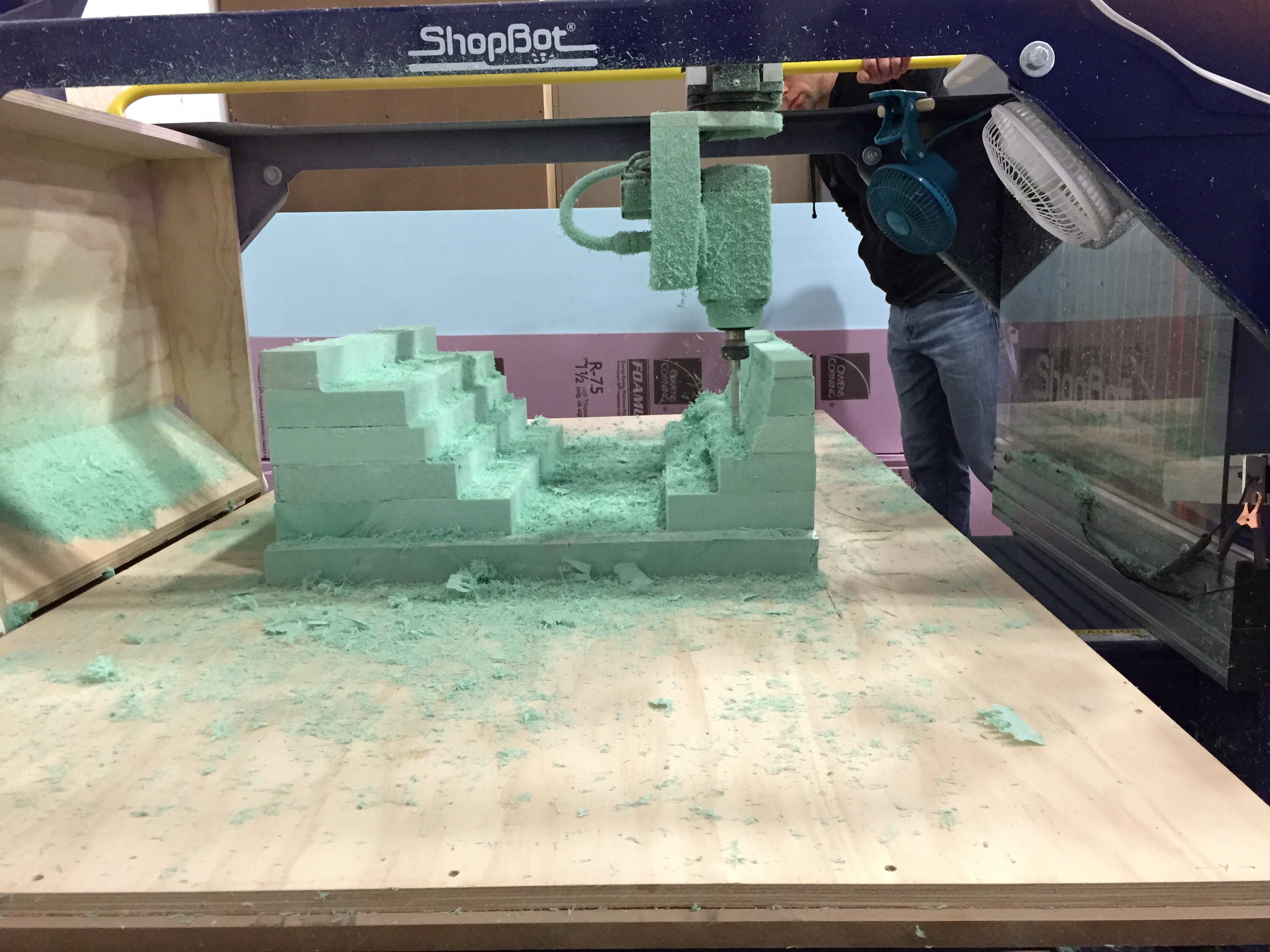

The first few carvings

A bit more grogress

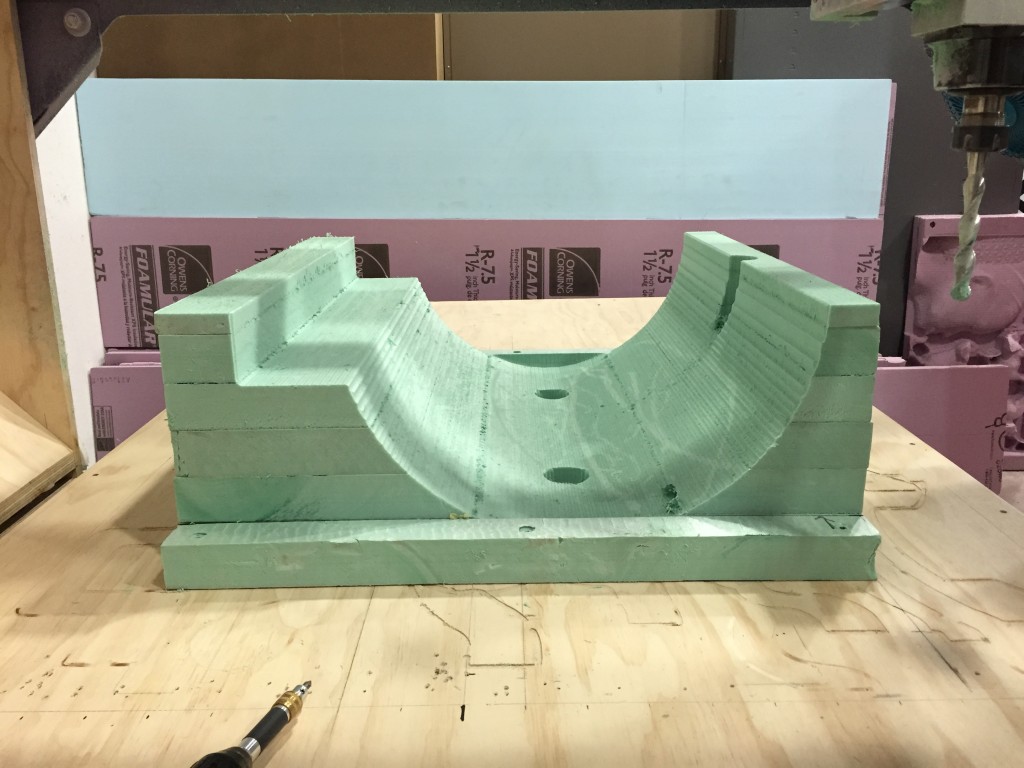

One whole piece is almost finished

Essentially done

Here is the bench assembled with a close up of the final products of the router

Click this link for a video I took of the router cutting

|

v